SHENZHEN-For one South China-based company, its walkie-talkies have to pass repetitive drop tests and button-pressing trials to meet factory inspection standards.

At Hytera, a leading walkie-talkie maker in Shenzhen, Guangdong province, most tests used to be conducted manually by quality inspectors.

"Workers pressing the on/off buttons tens of thousands of times a day were more prone to fatigue and ennui. The testing accuracy was also hard to guarantee," said Sun Meng, senior vice-president of the company.

In 2011, the company started upgrading its production line and introduced robots for intelligent manufacturing. Now, sorting, labeling and coding of raw materials, assembling of parts, handling of products and quality tests are being carried out by robots.

With more than 20 intelligent production lines, the company's production automation rate has surpassed 70 percent, Sun said.

"The yield rate and production have greatly improved," he said, adding that the number of factory workers has decreased from more than 3,000 to about 1,000.

The transformation of Hytera represents smart transition in the Pearl River Delta in Guangdong, with its cluster of manufacturers. Home to some 3 million industrial firms, the automation and digitalization of the manufacturing sector has become a virtual do-or-die strategy for high-quality development.

Bi Yalei, secretary-general of the Shenzhen Robotics Association, said with improved domestic industrial robotics technology and reduced prices, more enterprises have started to adopt cost-effective China-made robots for automation transformation, especially small and medium-sized manufacturers that are more cost-sensitive.

Figures show that the output of industrial robots in Shenzhen witnessed a 75.5 percent year-on-year growth in the first seven months, while the growth rate in the heavily industrialized city of Dongguan was 123.3 percent year-on-year in the first half. A report released by the association said the output value of industrial robots in Shenzhen reached 90.4 billion yuan ($14 billion) in 2020, up 9.98 percent from 2019. The growth was 7.65 percentage points higher than that of the previous year.

According to the provincial department of industry and information technology, more than 15,000 industrial enterprises are engaged in digital transformation using industrial internet technology, and over 500,000 companies have adopted cloud computing technology.

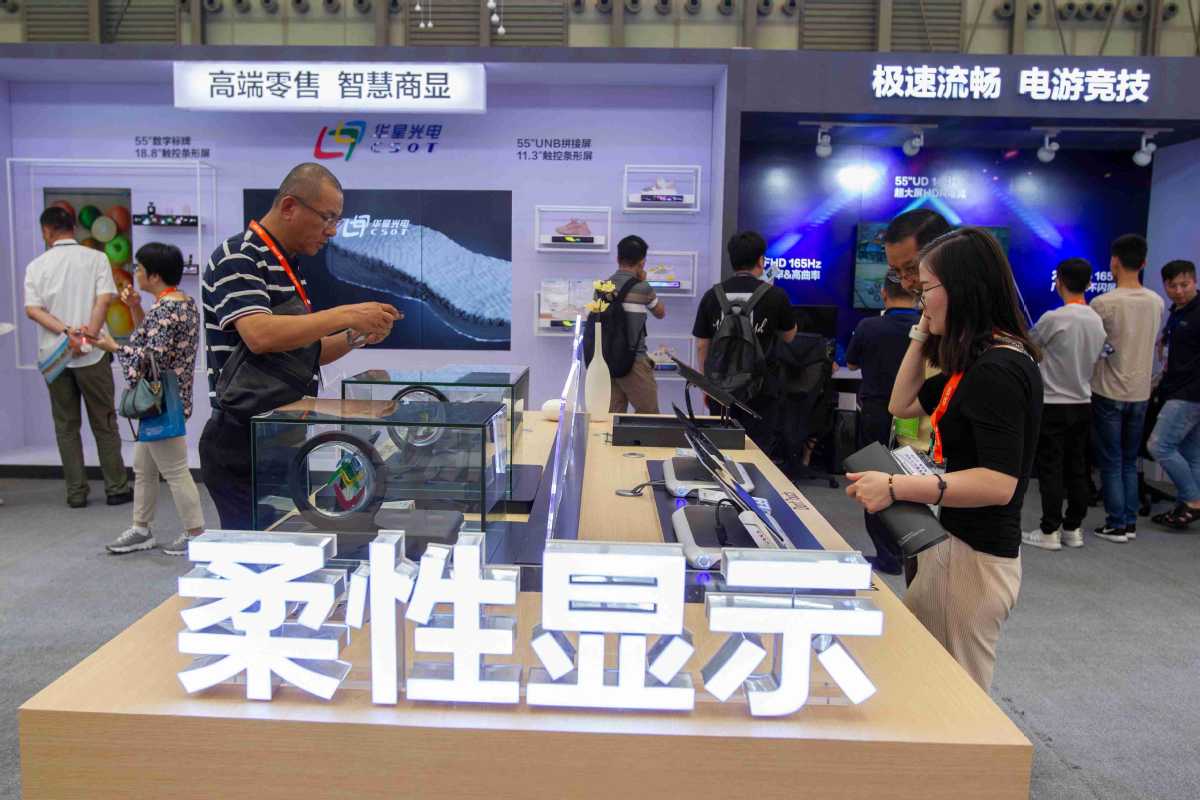

Introducing artificial intelligence technology, TCL China Star Optoelectronics Technology Co, a producer of semiconductor displays, has also replaced quality inspectors with robots, cutting the labor force of the sector by half and increasing efficiency nearly 10 times.

The company is trying to collect and analyze data of the entire production process, including temperature and humidity, hoping to further improve yield rates.

"We have to maximize production efficiency through high-level intelligence to further enhance the competitiveness of Made-in-China products," said Ding Liu'an, an employee with the digitalization office of the company.

Xinhua